In 2014, we started our first pelleting project with overwhelming results: 95% lower grease consumption of the pellet mills at lower operating temperatures and improved lifetime of roller bearings. Since then, we expanded significantly: Service teams, wood pellets, animal feed, spare parts and even commissioning of pellet mills.

Now, we are a full-service solution provider to the pelleting industries. With decades of experience, our service engineers help improving operational excellence. This includes lowering downtimes and improving efficiency through an assessment and actionable transition steps towards excellence. We help OEMs with commissioning, and provide service & repairs and spare parts to our customers.

We are happy to discuss improving your performance in person or a call. to get in touch with us write us an email info@bathan.ch or use the contact form.

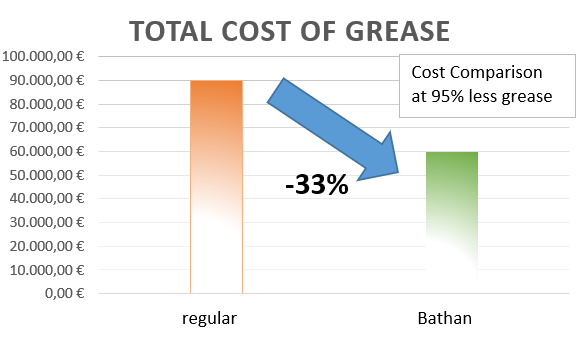

Our lubrication solutions help minimize lubrication volumes while mitigating downtimes, lowering the carbon footprint and improving reliability.

Dutch animal feed customer. Clean solution with 25 kg keg.

Animal feed producers benefit from a new standard in minimum volume lubrication according to FDA CFR 178.3570. With up to 98% lower grease consumption feed quality improves massively.

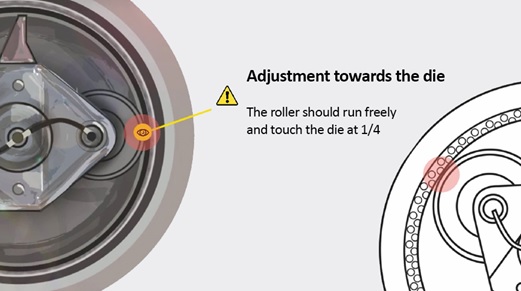

Animation on roller adjustment

We share our knowhow with operators.

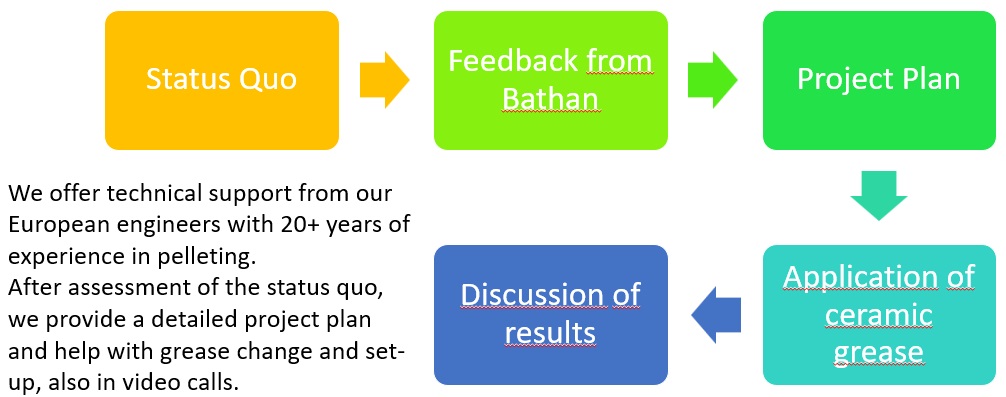

Switching grease is easy and hassle free.

Six weeks to success:

1 week – We assess the status quo and help preparing the transition.

4 weeks – The improved performance from Bathan grease application is recognized within four weeks.

1 week – Regular feedback, troubleshooting and regular performance discussions round up your success.

Usually, 2-digit TCG reductions are achieved

Disassebled roller in wood pelleting

We showcase our knowledge not only in our day-to-day business at our customer’s sites, but at several conferences and in industrial specific magazines.

International Biomass Conference & Expo

IBCE 2015 | Ceramic Lubricants in Pellet Mills

IBCE 2016 | Efficiency Improvements Through Streamlining Maintenance Processes

IBCE 2017 Update on Maintenance Best Practices

IBCE 2023 | Maintenance as a Key Performance Parameter

World Sustainable Energy Days (WSED) – European Pellets Conference

2015 | Ceramic Lubricants in Pellet Mills

2023 | Carbon Mitigation from a Pellet Plant Perspective

International Bioenergy Shanghai Conference and Expo (IBSCE) 2015

Pellet Fuel Institute (PFI ) Conference 2016

Streamlining of Maintenance Processes

Pellet Mill Magazine

July 2018 | From Plant to Plant – Lessons Learned

October 2018 | The Snares of Pelleting Mahogany Residues

December 2018 | Performance Despite Pests

February 2019 | Knowledge Management at Pellet Plants

April 2019 | Convincing Plant Managers to Spend Money

May 2019 | From Risk to Benfit

July 2019 | Contemplating Conveyor Safety

September 2019 | Run-to-Failure vs. Periodical Service

December 2019 | Germany’s Carbon Mitigation Plan with Biomass

January 2020 | Spare Part Reflections

March 2020 | Biomass’ Role in the European Green Deal

October 2020 | Experimenting with Grease Thickeners

April 2021 | Peanut Shells to Power

August 2021 | Quality Grease: Critical at Pellet Mills

November 2021 | Consequences of Load Strategy

August 2022 | The Influence of Material Flow on Pellet Mill Performance

February 2023 | Hammer Mill Maintenance: Keys to Performance